Amsterdam will halve the use of primary raw materials by 2030 and become fully circular by 2050 – according to the Circular Strategy 2020-2025 proposed by the municipality. To meet Amsterdam’s circularity ambitions and the increasing demand for schools, the city government has initiated the Innovation Partnership School Buildings program to build nine to thirty “high-quality, flexible and sustainable” schools in ten years. Circlewood – an alliance of architects, engineers, builders, and researchers, with OMA as the Creative Director and co-designer – has developed a modular wood system (the HoutKern Bouwmethode) to create a variety of schools, which can be easily transformed throughout the schools’ lifecycles to accommodate changing needs.

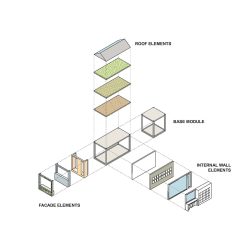

The prefabricated plug and play system consists of standardized wooden columns and cross-laminated wooden floor panels, which are connected by recycled steel joints. All the components are precisely made in the factory under a digitally controlled process to ensure fast assembly and disassembly by an electric crane on site. These components are arranged into 3.6 m wide, 7.2 m long, and up to three-storey high structural frameworks, leaving all the partition walls non-load-bearing to create spaces of different sizes and uses – from standard classrooms and offices, to auditorium and gymnasium, to gardens and athletic tracks. The biobased partition walls can be adapted to support different school activities such as indoor climbing and vertical farming. This system allows the school boards, the architects, and other consultants to work together to define schools with unique characters. The system – with the durable and easily assembled components – also enables the schools to expand, downscale, or vary in configurations as needs change.

Circlewood conceptualizes the schools not only as spaces for learning but also pedagogical tools that raise students’ consciousness of human impact on the environment. Contrary to greenwashing, the schools visualize their carbon footprint and resources consumption on information screens. The buildings are also inherently circular designs with minimized emissions: The prefabricated building method reduces nitrogen emissions by 80 percent compared with standard onsite construction. The biobased walls – made with carbon absorbing raw materials – are lighter and require less energy for transportation. At the end of the schools’ lifecycles, the buildings can be fully dismantled, and the components can be reused to create other types of buildings such as offices or homes.

As Circlewood’s Creative Director, OMA will help with the selection of young architectural practices and landscape designers, and develop in collaboration with them new schools under the Innovation Partnership School Buildings program. A pilot school in Amsterdam has been developed in collaboration with Studio A Kwadraat. Functioning as an integrated children’s centre, the compact building has a unique façade on each side, characterized by elements such as canopies and bike storage facilities that respond to the context and specific needs. The school has a spacious central hall for various children’s activities, and different types of façade openings that offer frameworks for the children to perceive the environment. As most technical challenges have been resolved through the development of the plug and play system, the program, layout and appearance of the building can be refined and adapted over time.

The current system designed by OMA and the Circlewood partners will be further developed, with the potential to be used for different types of buildings outside of Amsterdam and the Netherlands.

Circlewood consists of Noordereng Groep, Oosterhoff (ABT, Adviesbureau Lüning, bbn adviseurs), Studio A Kwadraat, DWA, Hedgehog Company, Heko Spanten B.V., EtuConsult, Lomans, Ferross Staalbouw, and OMA.

_