STUDIO NOUN . photos: © STUDIO NOUN . © Zsigmond Toth . + wbw

Timber craft has a long tradition in almost all cultures. In the face of the globalized industry and the digitalization of the craft, the project aims to present timber construction as an exemplary case of contemporary building and reminds us to preserve this cultural heritage. So, what would it mean to build a house made almost entirely of wood? The architectural concept for this project was driven by finding a sustainable way to build it. It meant minimizing the use of glue, metal, and concrete and avoiding the use of plastic altogether.

This radical approach led us to explore the potential of solid timber construction. It allows structures to be built without any of the components, like glue or metal, typically required to join elements together. A dozen layers of planks are laid crosswise and then joined transversely with beech wood dowels. The result is a wall made entirely of solid timber, which acts both as a load-bearing wall and as a thermal insulator thanks to the fine air pockets trapped between the layers of rough-sawn planks.

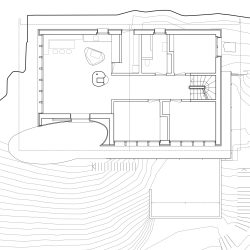

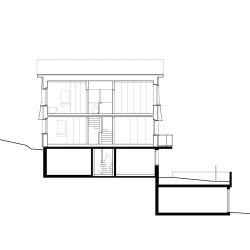

Similarly, all the interior finishes – doors, kitchen, paneling, flooring, and built-in cupboards – are made entirely from locally sourced timber. The spruce and fir used in the construction grew within a thirty-kilometer radius, were sawn at a nearby sawmill, and installed by local craftsmen. Local value creation and innovative prefabrication combine to create a sustainable low-tech architecture. The house is located in Unterwasser (Toggenburg) in a landscape of scattered houses. It replaces a house built in the early 1970s, which no longer offered enough space for the growing family. The foundations of the old house were retained to serve as a base for the new timber construction. As the house is located in an agricultural and cultural protection zone, it requires a sensitive approach with an awareness of the local building culture.

The façades quote elements typically found in local typologies. Ribbon windows running the length of the south and west façades are reminiscent of traditional houses, as is the exaggerated shed roof motif. Following the existing framework, the new geometry is linear. A free-form corner cut breaks this logic, creating a covered, wind-protected space with views into the valley. This gives the house a distinctive character and subtly distinguishes it from its surroundings. Inside, life is organized around a large double-height room where the central fireplace forms the qualitative and spatial heart of the house.

An open hallway runs through the center of the house, allowing full height and depth to be experienced. It flows seamlessly from the living area to the staircase leading to the top floor. From here, daylight enters the house through a large opening on the roof. The interior of the house is accentuated by a series of specially designed light fixtures. Their circular sockets are carved into the wood to create a series of growing circles, reminiscent of the annual rings of tree trunks.

_

Mit massivem Holz und ohne Kunststoff bauen – auf der Suche nach einer substantiell nachhaltigen Bauweise. Innovative Fertigungsmethoden, regionale Rohstoffe, lokale Handwerker. Lowtech durch Hightech. Obertoggenburg. Die typische Streusiedlung prägt das Landschaftsbild. Das Haus wurde Anfang der 1970er Jahre erbaut und liegt in der Landwirtschafts- und Kulturschutzzone. Die Obergeschosse wurden ersetzt und die bestehenden Untergeschosse neu verbunden. Der Holzbau orientiert sich an den bestehenden Grundmauern des Hauses. Kontrastierend dazu schafft ein freiförmiger Einschnitt in der Südwestecke des Hauses einen überdachten, windgeschützten Aussenraum. Die zentrale Diele als geschossübergreifend offener Bewegungsraum macht die gesamte Tiefe und Höhe des Hauses erlebbar. Der zentrale Speicherofen beheizt das Haus und verbindet Zirkulations- und Aufenthaltsräume. Im Süden und Westen erlauben Bandfenster über die gesamte Fassadenlänge den Blick auf die Churfirsten und den Alpstein. Tal- und bergseitig wird das ortstypische Motiv des „Abwurfdachs“ überzeichnet, indem die Schalung auf der gesamten Fassade bis unter den First angezogen wird. Das Projekt lotet aus, was mit aktuellem Stand der Technik im Massivholzbau ohne Einsatz von Klebstoffen möglich ist. Rohbau und Ausbau sind komplett aus massivem, lokalem Holz leimfrei konstruiert und mit neuster Technologie im Werk vorgefertigt. Die Fassadenverkleidung und Bodenriemen stammen aus einem nahegelegenen Waldstück, wurden durch die lokale Sägerei zugesägt und durch lokale Handwerker montiert.